Page 40 - Demo

P. 40

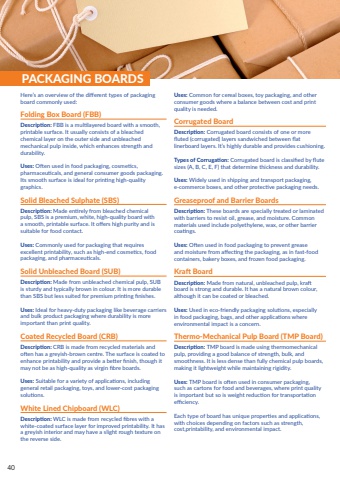

Here%u2019s an overview of the different types of packaging board commonly used:Folding Box Board (FBB)Description: FBB is a multilayered board with a smooth, printable surface. It usually consists of a bleached chemical layer on the outer side and unbleached mechanical pulp inside, which enhances strength and durability.Uses: Often used in food packaging, cosmetics, pharmaceuticals, and general consumer goods packaging. Its smooth surface is ideal for printing high-quality graphics.Solid Bleached Sulphate (SBS)Description: Made entirely from bleached chemical pulp, SBS is a premium, white, high-quality board with a smooth, printable surface. It offers high purity and is suitable for food contact.Uses: Commonly used for packaging that requires excellent printability, such as high-end cosmetics, food packaging, and pharmaceuticals.Solid Unbleached Board (SUB)Description: Made from unbleached chemical pulp, SUB is sturdy and typically brown in colour. It is more durable than SBS but less suited for premium printing finishes.Uses: Ideal for heavy-duty packaging like beverage carriers and bulk product packaging where durability is more important than print quality.Coated Recycled Board (CRB)Description: CRB is made from recycled materials and often has a greyish-brown centre. The surface is coated to enhance printability and provide a better finish, though it may not be as high-quality as virgin fibre boards.Uses: Suitable for a variety of applications, including general retail packaging, toys, and lower-cost packaging solutions.White Lined Chipboard (WLC)Description: WLC is made from recycled fibres with a white-coated surface layer for improved printability. It has a greyish interior and may have a slight rough texture on the reverse side.PACKAGING BOARDSUses: Common for cereal boxes, toy packaging, and other consumer goods where a balance between cost and print quality is needed.Corrugated BoardDescription: Corrugated board consists of one or more fluted (corrugated) layers sandwiched between flat linerboard layers. It%u2019s highly durable and provides cushioning.Types of Corrugation: Corrugated board is classified by flute sizes (A, B, C, E, F) that determine thickness and durability.Uses: Widely used in shipping and transport packaging, e-commerce boxes, and other protective packaging needs.Greaseproof and Barrier BoardsDescription: These boards are specially treated or laminated with barriers to resist oil, grease, and moisture. Common materials used include polyethylene, wax, or other barrier coatings.Uses: Often used in food packaging to prevent grease and moisture from affecting the packaging, as in fast-food containers, bakery boxes, and frozen food packaging.Kraft BoardDescription: Made from natural, unbleached pulp, kraft board is strong and durable. It has a natural brown colour, although it can be coated or bleached.Uses: Used in eco-friendly packaging solutions, especially in food packaging, bags, and other applications where environmental impact is a concern.Thermo-Mechanical Pulp Board (TMP Board)Description: TMP board is made using thermomechanical pulp, providing a good balance of strength, bulk, and smoothness. It is less dense than fully chemical pulp boards, making it lightweight while maintaining rigidity.Uses: TMP board is often used in consumer packaging, such as cartons for food and beverages, where print quality is important but so is weight reduction for transportation efficiency.Each type of board has unique properties and applications, with choices depending on factors such as strength, cost,printability, and environmental impact.40